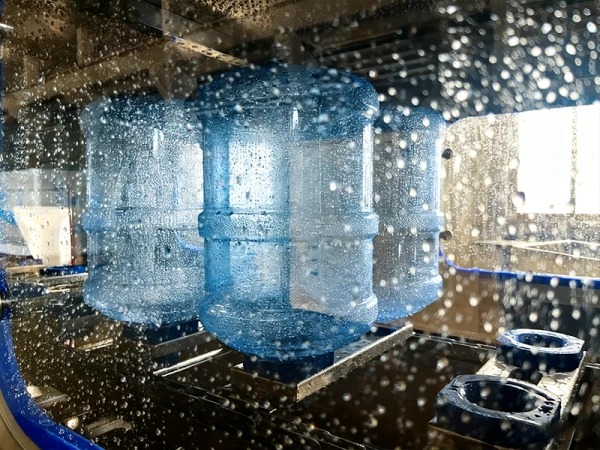

5 Gallon Water Filling Machine

Fully Automatic 5-Gallon / 3-Gallon Bottled Water Filling Line | Complete Turnkey Solution

Home » 5 Gallon Water Filling Machine

Why choose Newpeak's 5-gallon production line?

Multi-Purpose: Fill natural spring water, purified water, carbonated water, flavored water, and even hot-fill juices/tea by changing minimal parts.

3-in-1 Integration: Features combined Rinsing / Filling / Capping technology for compact design and higher efficiency.

Premium Components: Main structure made of SUS304/316 stainless steel. Pivotal electrical parts from SIEMENS, Mitsubishi, OMRON ensure reliability.

Cost-Efficient: Optimized process reduces consumption of water, electricity, and chemicals, lowering operational costs.

Hygienic Design: Complies with food safety standards with no dead-angles, dead-ends, or static liquid zones.

Detailed Equipment & Process Flow

Bottle Handling: Outer Washer (hot detergent) → Inner Washer (disinfectant & ozone water sterilization).

Aseptic Filling: Flowmeter-based Filler with valve descending for contact-free filling (±1% accuracy, drip-free).

Capping: Cap Washer (ozone) → Cap Feeder → Magnetic Torque Capper (adjustable, precise).

Quality Check: Light Inspection Box for final bottle and water clarity inspection.

Technical Specifications Table

| Item | Specification |

| Suitable Container | 3-5 Gallon PC/PET, Round or Square |

| Filling Method | Gravity Filling, Ambient Temperature |

| Production Capacity | 100 – 1500 BPH (Adjustable) |

| Filling Accuracy | ≤ ±1% |

| Power Supply | 380V, 3 Phase, 50Hz |

| Ambient Condition | Temperature: 10-40°C, No Dew |

| Main Material | SUS304 Stainless Steel |

| Control System | PLC (SIEMENS) + Touch Screen HMI |

The design of a 5-gallon water filling line is a crucial step in every customer project. We prepare a detailed proposal by analyzing customer requirements such as production capacity, bottle type, market demand, and raw water quality report.

Once the analysis is completed, we carefully select the most suitable 5-gallon filling machines and supporting equipment. The choice of machine models is closely linked to production efficiency, overall cost, and project budget, making it an essential part of the solution.

The design of a 5-gallon water filling line is a crucial step in every customer project. We prepare a detailed proposal by analyzing customer requirements such as production capacity, bottle type, market demand, and raw water quality report.

Technical parameter :5 gallon water filling machine

| Model | QGF-150 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| Capacity(for 5 gallon) | 150bph | 300bph | 450bph | 600bph | 900bph | 1200bph |

| Total power (KW) | 1.5kw | 3.8kw | 4.5kw | 5.2kw | 6.2kw | 7.8kw |

| Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

| Height | 1.8m | 2m | 2.2m | 2.3m | 2.5m | 2.6m |

| Weight(kg) | 800kg | 1500kg | 2000kg | 2500kg | 2800kg | 3500kg |

Customizable Solutions

Bottle Adaptation: Purchase change-over parts for different bottles. Bottle separating system added for square containers.

Layout Design: Complete production line CAD configurations available. Special layouts tailored to your factory floor.

Line Integration: Can be connected with blowing machines and packing lines for a complete turnkey beverage solution.

Service Advantages

We provide fast, reliable after-sales support worldwide, including installation, training, and 24/7 technical assistance, ensuring your production line operates efficiently with minimal downtime.

Comprehensive Technical Support

We provide technical support, including spare parts manuals, mechanical instructions, electrical schematics, and more. This ensures smooth equipment operation and greatly facilitates daily maintenance and management.

Premium Materials and Components

We always use high-quality raw materials and imported components to ensure stable, long-term equipment performance. Imported electrical parts are adopted to make future maintenance and replacement easier for our customers.

Extended After-Sales Guarantee

We provide a 24-month after-sales guarantee, offering free service and both online and on-site support within 24 months after equipment installation and commissioning.

Fast and Reliable Pre- and After-Sales Support

We provide fast, efficient service from pre-sales to after-sales. Quick design and layout support helps clients confirm orders faster, while our engineers ensure smooth installation, free spare parts, and ongoing technical support.

FAQ

Why should I choose an automatic production line over semi-automatic?

For much higher efficiency, consistent quality, lower labor costs, and better hygiene control in large-scale production.

Who typically uses a 5-gallon water filling line?

Bottled water plants, drinking water distributors, large enterprises, and beverage companies producing large-format packaged water.

When do I need to perform maintenance on the line?

Perform basic cleaning daily, lubrication weekly, and a full inspection of key parts like seals and sensors monthly or every 500 operating hours.

How does the machine handle different bottle shapes (round/square)?

By using interchangeable change-over parts. A bottle separating system is added specifically for handling square bottles.

How long does it take to install and commission the line?

Typically 1-3 weeks after delivery, depending on line complexity and site readiness. Our engineers provide on-site installation and training.

Successful Cases

Proven success delivering high-quality water solutions.