Carbonated Beverage Filling Machine

High-speed, precise, and reliable solutions for PET bottles, glass bottles, and cans.

Home » Carbonated Beverage Filling Machine

Carbonated Beverage Isobaric Filling Machine

Our Carbonated Beverage Isobaric Filling Machine is designed for soda, sparkling water, beer, and other carbonated drinks. Adopting advanced isobaric filling technology, it ensures precise liquid levels, high filling speed, and minimal CO₂ loss. Featuring smooth bottle handling, hygienic design, and easy operation, the system guarantees consistent product quality and long-lasting freshness. With high efficiency, low maintenance, and flexible customization, it is the ideal choice for modern beverage production lines.

Carbonated Beverage Filling Machine Description

The Isobaric Filling Machine is engineered for carbonated beverages such as cola, soda, sparkling water, and beer. Using advanced pressure-filling technology, it maintains carbonation and ensures uniform filling without foaming or spillage. The machine is equipped with intelligent controls, durable components, and a user-friendly interface, making it suitable for both small and large-scale production. Designed for efficiency and reliability, it delivers stable performance, low energy consumption, and long service life, helping beverage producers achieve consistent quality and higher output.

The DCGF Series Carbonated Drink Filling Machine is a fully automatic 3-in-1 system for producing soda water, soft drinks, and sparkling water. Designed for PET and other plastic bottles, it seamlessly combines rinsing, filling, and capping in a compact structure, delivering high efficiency, hygienic operation, and stable performance.

Filling System:

- Mechanical valve

- Flow meter

- Carbonator

- Isobaric (iso-pressure) filling technology

Technical Specifications

Capacity: 2,000 – 36,000 BPH | Filling Type: Equal Pressure | Application: Carbonated Drinks, Soft Drinks, Sparkling Water, Energy Drinks, Beer

| Technical parameter : carbonated beverage production line | ||||||

| Model | DCGF14-12-5 | DCGF16-16-6 | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-10 | DCGF40-40-12 |

| Capacity(for 500ml) | 2000-3000 | 3000-4000 | 4000-5000 | 8000-9000 | 11000-12000 | 13000-15000 |

| Suitable bottle shapes | circular or square | |||||

| Bottle diameter(mm) | Dia50-Dia115mm | |||||

| Bottle height (mm) | 160-320mm | |||||

| Compressor air | 0.3-0.7Mpa | |||||

| Washing meidium | Aseptic water | |||||

| Rinsing pressure | >0.06Mpa <0.2Mpa | |||||

| Application | carbonated beverage production line | |||||

| Total power (KW) | 4.4kw | 4.8kw | 5.2kw | 6.2kw | 7.5kw | 8.2kw |

| Overall dimensions | 2.5*1.9m | 2.7*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.6m |

| Weight(kg) | 3000kg | 4000kg | 4500kg | 6000kg | 8500kg | 10000kg |

Container Compatibility

Container Type | Material | Bottle Shape | Filling Volume | Neck Type | Notes |

| PET Bottle | Plastic | Round / Square | 100-2000 ml | Screw Cap | Adjustable bottle diameter ≤105 mm, height ≤335 mm |

| Glass Bottle | Glass | Round / Square | 200-1000 ml | Screw Cap/Aluminum lid | Premium appearance, precise filling & capping |

| Can | Aluminum | Standard | 250-500 ml | Pull Tab | High-speed canning, maintains carbonation |

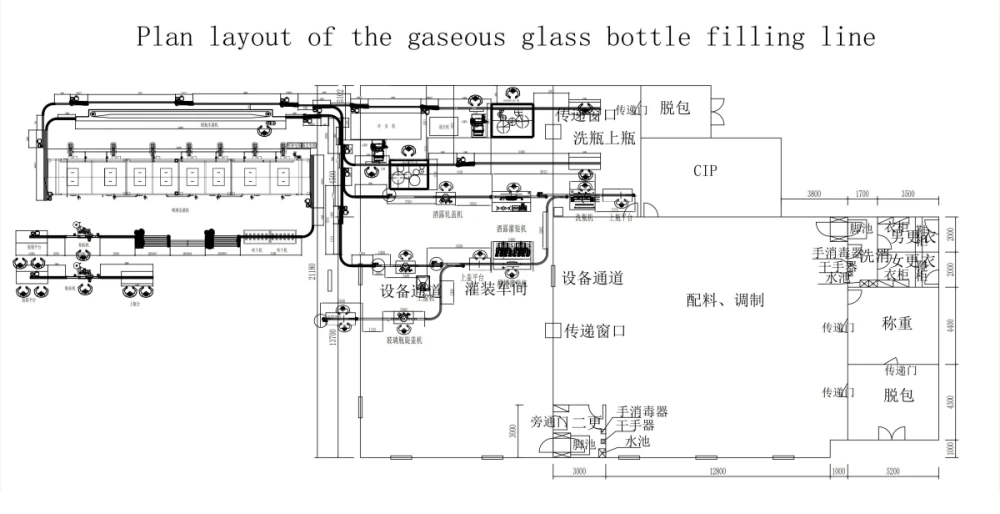

Carbonated Beverage Filling Line Solution

Our Carbonated Beverage Filling Line Solution provides a complete, automated process for soda, soft drinks, sparkling water, and beer production. The system integrates bottle rinsing, isobaric filling, capping, labeling, and packaging in one streamlined line. With advanced CO₂ preservation technology, precise liquid control, and hygienic design, it ensures consistent product quality and long-lasting freshness. Engineered for high efficiency, flexibility, and durability, this solution helps beverage manufacturers boost productivity while reducing operating costs.

Water Treatment Equipment

Our Water Treatment Equipment is designed to provide clean, safe, and high-quality water for beverage production. The system integrates multiple purification processes, including filtration, reverse osmosis, UV sterilization, and mineral adjustment, ensuring the water meets strict food-grade standards. With reliable performance, easy operation, and customizable configurations, it guarantees consistent water quality while reducing energy consumption and maintenance costs. This makes it an ideal solution for bottled water plants and beverage filling lines.

Beverage Blending System

Our Beverage Blending System is designed to accurately mix water, syrup, juice concentrate, and other ingredients to achieve consistent taste and quality. The system features precise flow control, automatic ratio adjustment, and sanitary design to meet food-grade standards. With easy operation, high blending efficiency, and compatibility with various beverage formulations, it ensures stable product quality while reducing material loss and production costs. This solution is ideal for juice, carbonated drinks, dairy beverages, and other liquid food industries.

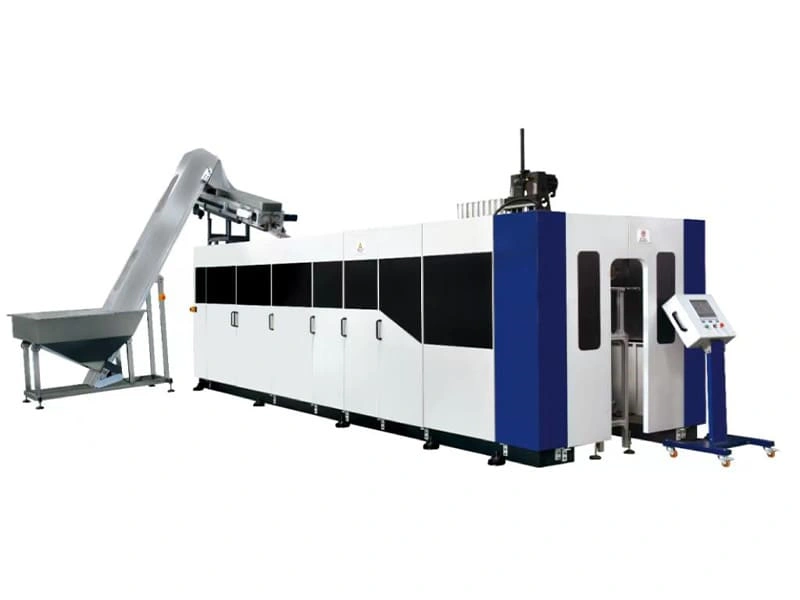

Automatic Bottle Blowing Machine

Our Automatic Bottle Blowing Machine is specially designed for producing high-quality PET bottles in various shapes and sizes. Using advanced heating and stretch-blowing technology, it ensures uniform wall thickness, strong bottle durability, and excellent transparency. The system features high-speed production, low energy consumption, and easy operation, making it an efficient and cost-effective solution for beverage, water, and food packaging industries. With customizable molds and flexible capacity options, it meets diverse production demands while maintaining stable performance.

Carbonated Beverage Filling Machine

The Carbonated Drink Filling Machine is designed for soda, soft drinks, sparkling water, and other carbonated beverages. It adopts advanced isobaric filling technology to maintain carbonation, reduce foaming, and ensure precise liquid levels. Integrated with rinsing, filling, and capping functions, the system offers high efficiency, hygienic operation, and reliable performance. With flexible capacity options and user-friendly controls, it provides an ideal solution for modern beverage production lines, helping manufacturers improve output and reduce costs.

Automatic Pressure-Sensitive Labeling Machine

Our Automatic Pressure-Sensitive Labeling Machine is designed for applying adhesive labels on bottles, jars, and containers with high precision and speed. The system features adjustable label placement, smooth operation, and minimal downtime, ensuring consistent, professional results. With hygienic construction and easy integration into production lines, it is ideal for beverage, food, and pharmaceutical industries seeking efficient and reliable labeling solutions.

Integrated Shrink Wrapping Machine

Our Integrated Shrink Wrapping Machine is designed for efficient and compact packaging of bottles, cans, and other containers. Combining sealing, wrapping, and shrinking functions in a single unit, it ensures secure, neat, and professional packaging. The system features high-speed operation, easy adjustment, and reliable performance, making it ideal for beverage, food, and consumer goods production lines. With hygienic design and low maintenance requirements, it helps manufacturers improve productivity and reduce packaging costs.

Our Solution Development Process

Tailored production line solutions for your unique business requirements

Needs Assessment

Our team collaborates with you to fully understand your production objectives, beverage type, output volume, available space, and budget, ensuring the solution fits your specific requirements.

Custom Design

We create a personalized solution that combines the ideal equipment, layout, and technology to maximize your production efficiency and ensure consistent product quality.

Engineering & Planning

Our engineering team develops detailed specifications, 3D layouts, and project timelines to guarantee seamless integration with your existing operations.

Manufacturing & Delivery

We manufacture your custom equipment in our advanced facilities, performing strict quality inspections before delivering it to your site.

Engineering & Planning

Our engineering team develops detailed specifications, 3D layouts, and project timelines to guarantee seamless integration with your existing operations.

Installation & Training

Our technicians handle system installation and commissioning, then provide thorough training to ensure your team operates it efficiently and safely.

FAQ

Can your machine handle bottles of different sizes?

Yes, bottle height and diameter are adjustable. Additional change-over parts may be required for large size differences.

Are PET plastic bottles and glass bottles compatible?

Yes, with specific filling heads and optional canning modules.

How long for installation?

Equipment production will be completed within 30 days, and installation will take 10-25 days depending on the project scale.

What about maintenance and spare parts?

One-year warranty, spare parts provided, lifetime technical support available.

What is the maximum production capacity?

Up to 36,000 BPH for 500ml PET bottles, lower capacities for larger bottles or cans.

Successful Cases

Proven success delivering high-quality water solutions.