Oil Filling Machine

Engineered for Accuracy, Hygiene & Efficiency in Edible & Industrial Oils

Home » Oil Filling Machine

Precision Filling, Guaranteeing the Quality of Every Drop

Newpeak provides a complete range of filling solutions for edible and industrial oils in PET bottles, glass bottles, and tinplate cans. We understand the stringent requirements for filling accuracy, hygiene standards, zero residue, and leak prevention in oil products. Leveraging years of specialized expertise, we deliver stable and reliable turnkey production line solutions.

Application Scope: Peanut oil, olive oil, palm oil, blended oil, lubricating oil, hydraulic oil, honey, and other viscous liquids.

Oil Filling Line

Newpeak designs and supplies a wide range of filling lines for bottles (0.1–5L), drums (5–30L) and other vessels of varying capacities. With extensive experience in oil filling, we have continuously optimized our equipment design. Our machines are engineered to handle the unique properties of oils, ensuring high filling accuracy without dripping. All contact surfaces are made from food-grade materials, meeting the strict standards required for filling oils, sauces, and other food products.

→ High Filling Accuracy

Ensures precise volume control for each container, significantly reducing product waste and improving cost efficiency. Ideal for operations where consistency is critical.

→ Drip-Free Design

Advanced nozzle and sealing technology prevent any leakage during the filling process, maintaining a clean production environment and minimizing product loss.

→ Fast Production Speed

Optimized mechanical and control systems allow rapid filling cycles, increasing overall output and meeting high-volume production demands.

→ Durable Construction

Built with robust materials and components, including stainless steel frames and corrosion-resistant parts, guaranteeing long-term reliability and stability under continuous operation.

→ Easy Operation

Intuitive interface, simple controls, and automated features make it easy for operators to use, reducing training time and operational errors.

→ Low Maintenance

Designed for easy cleaning and quick maintenance, minimizing downtime and keeping operational costs low while maintaining consistent performance.

→ Versatile Application

Suitable for a wide range of liquid products, including edible oils, lubricants, sauces, and other similar fluids, making it flexible for various production lines.

→ Food-Grade Materials

All contact surfaces are made from certified food-grade materials, ensuring safety, hygiene, and compliance with strict food industry standards.

→ Customizable Options

Can be tailored to fit different container types and sizes, from small bottles to large drums or IBC tanks, allowing adaptation to diverse production needs and facility layouts.

Core Processes & Technological Advantages

Precision Filling Systems (Multiple Technologies for Diverse Needs)

| Filling Technology | Principle & Characteristics | Suitable Products & Accuracy |

|---|---|---|

| Servo-Weight Filling | Each valve driven by an independent servo motor enables segmented high/low-speed control. Core anti-drip device ensures no clinging or residue on the bottle mouth. | High-value edible oils (e.g., Olive oil) Accuracy: ±1g |

| Flowmeter Filling | Real-time measurement via high-precision flow meters with PLC closed-loop control. Excellent speed and accuracy, easy to clean. | Various viscosity edible oils, lubricants Accuracy: ±2-3g |

| Piston Volumetric Filling | Mechanical metering, highly adaptable to product viscosity, extremely stable performance, simple maintenance. | Sauces with particles, high-viscosity industrial oils |

| Gravity Filling | Relies on liquid level difference for natural filling. Simple structure, suitable for high-end oils sensitive to shear force. | Premium cold-pressed oils |

Hygiene & Material Design

Contact Materials: All parts in contact with the product are made of 316L stainless steel. Seals are made of food-grade silicone or PTFE material, ensuring zero contamination and corrosion resistance.

Zero Residue Design: The valve interior features mirror polishing and a special flow channel design, combined with a vacuum suction function, to completely eliminate dripping and residue problems.

CIP/SIP System: Supports online cleaning and online sterilization processes. No disassembly of pipes or valves is required, meeting the high hygiene standards of food-grade production.

Intelligent & Stable Control

Neck-Holding Conveyance: Bottles are conveyed by neck grippers with bottom support plates, ensuring smooth operation and significantly reducing parts and adjustment time for bottle changeovers.

Modular Quick-Change Design: Change parts like star wheels, guide plates, and grippers use tool-free quick-change structures, reducing changeover time to under 30 minutes.

Fully Automated Line Integration: Can be seamlessly integrated with blow molders, labelers, coders, case packers, and palletizing robots to achieve full automation from raw material to finished product.

Typical Production Line Configurations

Solution A: High-Speed PET Bottle Edible Oil Filling Line (2,000 - 18,000 BPH)

Empty Bottle Sterilization → Servo-Weight Filling → Nitrogen Flushing (Optional) → Screw Capping/Press Capping → Heat-Shrink Sleeve Sealing → Vertical Round Bottle Labeling → Weight Check → Case Packing → Palletizing

Features: Suitable for 1L-5L family-sized edible oil. Nitrogen flushing effectively prevents oil oxidation, extending shelf life.

Solution B: Premium Glass Bottle Gourmet Oil Filling Line (1,000 - 6,000 BPH)

Bottle Body Vision Inspection → Sterile Air Blow-Off → Gravity Precision Filling → Vacuum Cap Suction & Screw Capping → Foil Sealing (Optional) → Neck-Oriented Labeling → Shrink Film Packaging

Features: Maximizes preservation of oil flavor and nutrients. Elegant appearance enhances product premium feel.

Solution C: Industrial Lubricant Filling Line (For 5L-20L Square Containers)

Automatic Container Feeding → Piston Volumetric Filling → Press Capping/Screw Capping → Anti-Counterfeit Labeling → Coding → Automatic Boxing/Stretch Wrapping → Pallet Output

Features: High filling accuracy, optional explosion-proof design, meets high-capacity, high-efficiency needs in the industrial sector.

Technical Parameter Overview (Customizable per Requirements)

Technical parameter : Oil Filling Machine | |||

Model | OGF24-8 | OGF32-10 | OGF40-12 |

Capacity(for 1000ml) | 7000-8000 | 10000-11000 | 12000-13000 |

Suitable bottle shapes | Circular or square | ||

Bottle diameter(mm) | Customized | ||

Bottle height (mm) | Customized | ||

Filling type | Weigh filling type / Piston Filling type / Flow meter filling type | ||

Function | Filling capping | ||

Application | Oil | ||

Total power (KW) | 4.4kw | 5.4kw | 6.4kw |

Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m |

Height | 2.3m | 2.5m | 2.5m |

Weight(kg) | 3500kg | 5200kg | 7000kg |

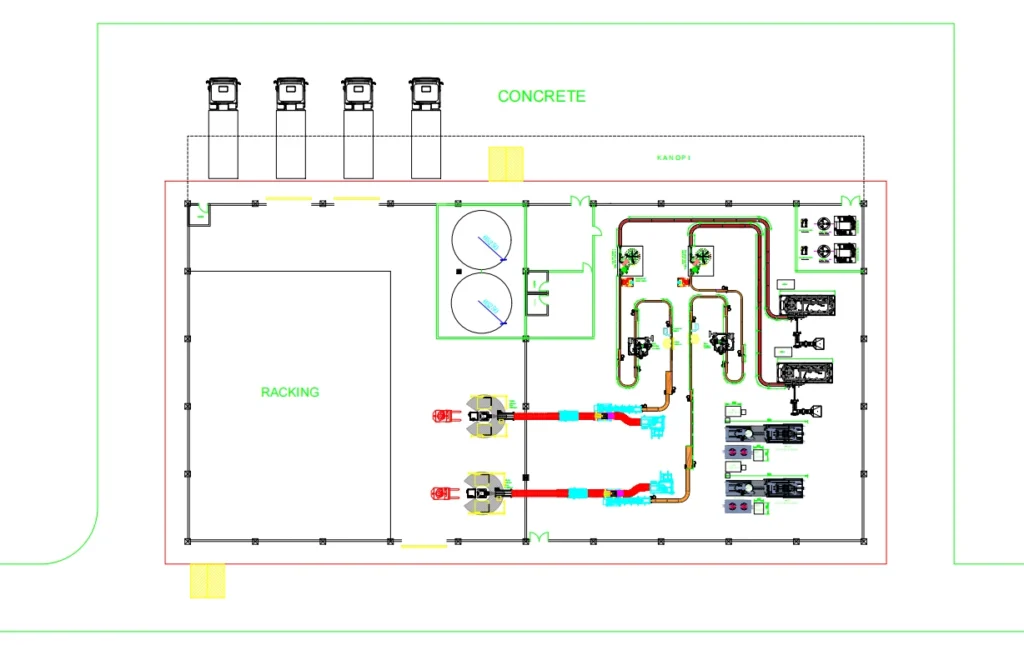

Indonesian Oil Production Line

Capacity: 500ml/1000ml

Production Capacity: 8000 bottles per hour

Our Oil Filling Machine delivers precise and efficient filling for edible oils, sauces, and lubricants. It supports 0.1–5L bottles drums, using drip-free nozzles and high-accuracy flow meters to ensure consistent filling without waste. All contact parts are food-grade stainless steel, meeting strict hygiene standards.

The system features accurate mechanical/electronic valves, easy-to-use controls, and a modular design for quick changeover and simple maintenance. Built for durability and continuous operation, it provides a clean, reliable, and highly efficient solution for modern oil filling production lines.

| Project Name: Automatic Piston / Flowmeter Filling Machine | Oil and Fat Products | |||

| Bottle Material | Bottle Shape | Filling Range | Filling Heads | Production Capacity |

| PET / PP / PE / Glass / Metal | Round / Square / Unique Shape | 0.2L-6L | 4-50 | 1000-20000bph |

| Filling Valve | Each filling valve is controled by servo motor ,realizing segmented high-and low-speed control ; vacuum resorption devices without leakage. | |||

| Cap Closing Method | Applicability for both crowning and capping, mechanical instant sealing or servo controlled sealing | |||

| Bottle Components | Rapid replacement without tools, such as star wheels for bottle infeed and outfeed, and bottleneck clamps | |||

| Filling Precision | Limit deviation: ±2-3g Standard deviation: 1.5 | |||

| User Ambient Conditions | Temperature: 10~40℃ Humidity: No dew | |||

| User Electrical Supply Specification | Voltage: 380V±5% 3phase Frequency: 50HZ±1% | |||

Why Buy Oil Filling Machine From Newpeak?

Newpeak provides reliable, high-precision oil filling machines with drip-free nozzles and food-grade materials. Customizable, easy to operate, and backed by expert support, our solutions help boost efficiency, reduce waste, and ensure consistent product quality.

√ Customized Solution

We provide tailored filling line solutions to meet your unique production needs. From container types and volumes to beverage formulas, we design equipment and workflows that optimize efficiency, ensure accurate filling, and adapt perfectly to your facility layout.

√ Perfect Service

Our team offers comprehensive support from pre-sales consultation to after-sales maintenance. With installation guidance, staff training, and ongoing technical assistance, we ensure your production line operates smoothly and reliably at all times.

√ Lower Cost

Our equipment is engineered for energy efficiency, minimal product waste, and easy maintenance. By optimizing production processes and reducing operational costs, we help you maximize profitability while maintaining high-quality output.

√ Reliable Quality

We use high-quality, food-grade materials and durable components to guarantee long-lasting performance. Every machine undergoes strict quality checks to ensure stable operation, precise filling, and consistent product standards for your business.

FAQ

How does Newpeak's filling machine ensure extremely high filling accuracy?

We employ a multi-stage control strategy. First, precise segmented high/low-speed control of the filling valve via servo motors. Second, real-time feedback and compensation from core load cells or mass flow meters. Finally, a unique vacuum suck-back anti-drip valve ensures zero residue at the moment of closure. Comprehensive accuracy can reach up to ±0.1%.

Will filling viscous oils (e.g., sesame oil, engine oil) clog the valves?

No. For high-viscosity products, we offer large-diameter piston valves or flowmeter systems with heating jackets. Valve channels are specially polished, and pipeline heating can be optionally configured to prevent oil condensation. Furthermore, the powerful CIP system thoroughly cleans all contact parts.

Is changing bottle formats complicated and time-consuming?

It’s very quick. Newpeak production lines utilize “neck-holding” conveyance and modular quick-change design. Changing bottle formats typically only requires replacing a few components like star wheels, grippers, and guide plates, most of which are tool-free. Full line changeover can be completed within 30-60 minutes.

Does the equipment support nitrogen flushing to extend edible oil shelf life?

Yes. We can integrate an inline nitrogen generation and flushing system. Before capping, food-grade nitrogen is injected into the bottle headspace to displace oxygen, effectively inhibiting oil oxidation and rancidity, significantly extending product shelf life.

Can Newpeak provide a fully automated packaging line solution?

Absolutely. We are a complete line solution provider. In addition to the core filling and capping machine, we can also supply: fully automatic blow molders, OPP/pressure-sensitive labelers, checkweighers, vision inspection systems, case erectors/packers, and robotic palletizing systems, achieving full automation from empty containers to finished pallets.

Successful Cases

Proven success delivering high-quality water solutions.