Beer Filling Machine

Newpeak is a leading manufacturer of fully automatic beer filling machines, providing complete beer bottling line solutions including glass bottle washing, isobaric filling, capping, labeling, packaging, and pasteurization.

Home » Beer Filling Machine

Beer Filling Line

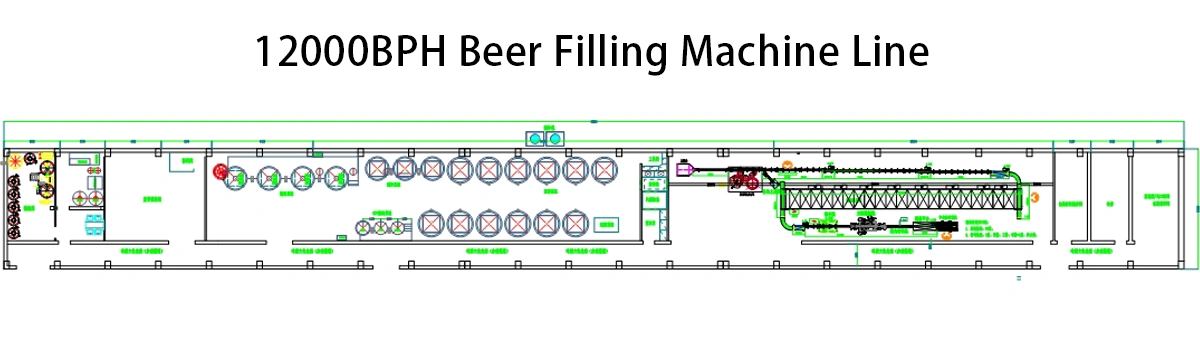

- The complete bottled beer production line includes seven main sections: water treatment, blending system, filling system, sealing system, labeling system, packaging system, and conveying system.

- Fully automatic operation significantly boosts production efficiency while reducing labor requirements.

- Advanced foreign CO₂ mixing technology ensures precise carbonation levels in the finished product.

- With our unique domestic sealing technology and wire capping machine, we are the only supplier capable of providing a full production line for champagne.

- Equipped with international electrical brands like Siemens and Schneider, the entire line operates with enhanced stability and reliability.

This production line is primarily designed for glass-bottled carbonated beverages, including champagne and sparkling wine.

Specification of Bottles

Glass bottle

Volume 330 – 750ml

Bottle diameter 65-100mm

Bottle height 170-330mm

Beer Filling Machine Flow Chart

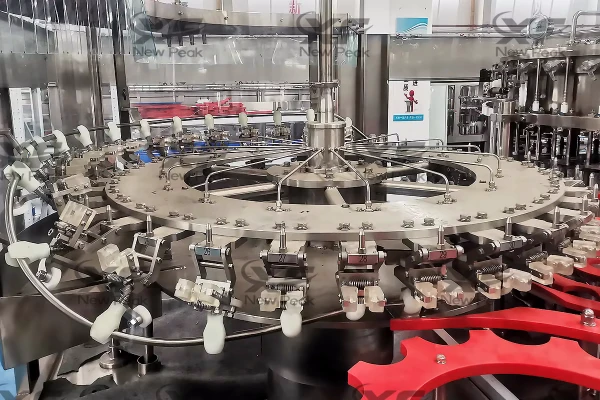

The beer isobaric filling machine provides efficient, high-speed, and hygienic filling for carbonated beverages such as beer, sparkling wine, and soda. Using equal-pressure technology, it preserves carbonation and prevents foaming, ensuring consistent taste and quality.

Complete Beer Bottling Line Solution

Newpeak provides a turnkey beer filling production line, including:

- Glass Bottle Washing Machine

Advanced German-style design, soaking + spray cleaning. - Beer Washing Filling Capping Machine (BGF Series)

Full isobaric system with low oxygen control. - CO₂ Supply & Buffer System

Stable pressure for perfect isobaric filling. - Tunnel Pasteurizer (Beer Pasteurization Tunnel)

Ensures product stability and shelf life. - Beer Labeling Machine (OPP / Sleeve / Sticker)

- Automatic Packing Machine

Carton packing or film wrapping. - Automatic Palletizer System

- CIP System / Water Treatment System

Beer Filling Machine Specifications

Our beer filling machines support customizable capacities from 1,000 to 24,000 bottles per hour, tailored to your production needs.

Model | BDCGF14-12-5 | BCGF18-18-6 | BDCGF24-24-8 | BDCGF32-32-10 | BDCGF40-40-12 | BDCGF50-50-15 | BDCGF60-60-20 |

Capacity(for 500ml) | 2000-2500 | 2500-3000 | 3000-5000 | 6000-8000 | 10000-12000 | 12000-15000 | 15000-18000 |

Suitable bottle shapes | Circular or square/customizable | ||||||

Bottle diameter(mm) | Dia50-Dia115mm/customizable | ||||||

Bottle height (mm) | 160-320mm/customizable | ||||||

Compressor air | 0.3-0.7Mpa | ||||||

Washing meidium | Aseptic water | ||||||

Rinsing pressure | >0.06Mpa <0.2Mpa | ||||||

Application | water bottling plant sale | ||||||

Main motor power | 2.8KW | 2.8KW | 3KW | 4KW | 7.5KW | 7.5KW | 7.5KW |

Overall dimensions | 3.0*2.2m | 3.2*2.2m | 3.2*2.3m | 3.7*2.6m | 5.0*4.0m | 5.5*4.5m | 6.0*6.0m |

Height | 2.4m | 2.4m | 2.4m | 2.5m | 2.5m | 2.5m | 2.5m |

Weight(kg) | 3000 | 3500 | 4000 | 5000 | 5500 | 6000 | 7000 |

Core Technology Highlights

1️⃣ High-Precision Isobaric Filling System

Multi-stage pressure control

Anti-foam design

Accurate liquid level control

Oxygen content significantly lower than traditional filling systems

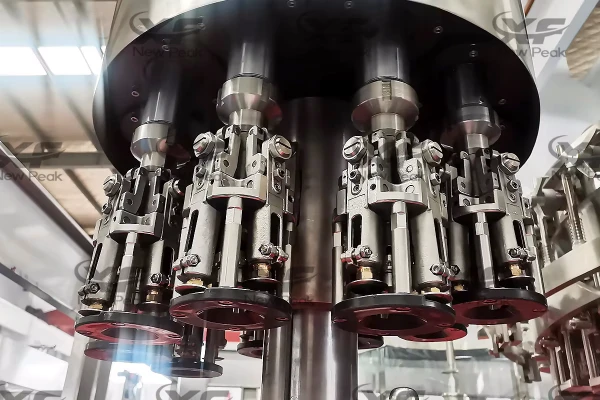

2️⃣ Stainless Steel Filling Heads (304 / 316L)

Smooth interior polish

No dead corners

Easy CIP cleaning

3️⃣ Advanced Magnetic Capping Technology

“Place-and-capping” for gentle handling

Auto stop when bottles missing

Defect rate ≤ 0.2%

Industry Trends & Latest Updates (2024–2025)

1. Low-Oxygen Filling Becomes Industry Standard

More breweries now require <0.03 mg/L dissolved oxygen for better flavor stability, achievable with advanced low-DO isobaric filling technology.

2. Rise of Craft Beer & Small Batch Production

Mini lines (1000–3000 BPH) become popular.Newpeak launches compact craft beer bottling machine with 30% smaller footprint.

3. High-Speed Automated Beer Lines

Large breweries demand >36,000 BPH production.Our upgraded servo-driven filling valves support higher speeds with lower foaming.

4. Smart Factory Integration (IoT + AI)

Newpeak systems now support:Real-time oxygen monitoring,Remote diagnostics,Predictive maintenance algorithms

Future Outlook of Beer Filling Machines

1. Fully Smart Beer Bottling Line (AI-driven Plant)

Predictive maintenance → 30% fewer machine stoppages.

2. More Hygienic Designs (Full 316L Lines)

Future standards will focus on eliminating hidden contamination points.

3. Zero-Loss Filling Technology

Reducing beer loss to <0.1% will become the new benchmark.

4. Sustainability & Energy Saving

Eco-friendly steam systems & 20% energy reduction pasteurizers.

5. Plug-and-Play Microbrewery Lines

Fast installation → designed for small craft breweries worldwide.

FAQ

Why do breweries prefer isobaric beer filling machines?

Because isobaric filling controls pressure and CO₂ levels, reduces foaming, and achieves low dissolved oxygen—essential for maintaining beer freshness and flavor stability.

What sizes and bottle types can a beer bottling machine handle?

Most machines support 330ml, 500ml, 650ml,750ml glass bottles, aluminum cans, PET bottles, and custom craft beer bottle shapes. Change parts allow fast bottle-size switching.

How does a beer filling machine control dissolved oxygen?

By using CO₂ pre-evacuation, double vacuuming, counter-pressure filling, and deaeration nozzles. These steps help achieve ultra-low DO levels required by modern breweries.

Why is a tunnel pasteurizer important in a beer production line?

It kills microorganisms, stabilizes flavor, and extends shelf life. For export beer, pasteurization ensures quality during long-distance shipping.

What maintenance is required for a beer bottling line?

Regular lubrication, CIP cleaning, replacing seals, checking CO₂ pressure, and monitoring filling valves. Proper maintenance ensures hygienic and stable production.

Successful Cases

Proven success delivering high-quality water solutions.