Table of Contents

-

Why Industrial Water Treatment System Cuts Costs for Factories

-

RO Water Treatment System vs. Traditional Purification

-

Key Features of Our Reverse Osmosis Water Treatment machine

-

Tips to Choose the Right Water Treatment System

-

FAQs About Industrial Purification System

Factories and industrial plants know water costs add up fast—from raw water fees to wastewater disposal! And when it comes to cost-saving, ro water treatment machine options are total game-changers.

Why Industrial Water Treatment System Cuts Costs for Factories

You might think a new water treatment system is a big investment, but the savings quickly outweigh it! Here’s how:

-

Water Reuse: Treated water can be recycled for cooling towers or cleaning—cuts raw water purchases by 30-50%!

-

Lower Disposal Fees:合规的 treated wastewater avoids costly fines and reduces disposal charges.

-

Less Equipment Wear: Purified water prevents scale buildup in machinery, extending lifespan by years.

RO Water Treatment System vs. Traditional Purification

Traditional methods like chemical treatment are outdated—here’s how reverse osmosis water treatment machine wins:

|

Feature

|

RO Water Treatment System

|

Traditional Chemical Treatment

|

|---|---|---|

|

Cost Over Time

|

Low (energy-efficient, no chemical refills)

|

High (ongoing chemical purchases)

|

|

Purification Rate

|

Removes 99.9% impurities

|

Inconsistent, leaves chemical residues

|

|

Environmental Impact

|

Eco-friendly, minimal waste

|

Chemical runoff risks

|

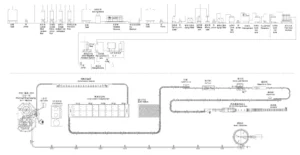

Key Features of Our Reverse Osmosis Water Treatment machine

Our industrial water treatment machine is built for real factory needs—here’s what makes it stand out:

-

Auto-Flush Technology: Cleans RO membranes automatically, reducing maintenance time by 40%.

-

Energy-Saving Pumps: IE4 motors use 20% less electricity than standard models—huge monthly savings!

-

Scalability: From 5T/h to 500T/h capacity—grows with your business, no need to replace the whole system.

-

Smart Monitoring: PLC touchscreen tracks water quality and system status—alerts you before issues arise.

Tips to Choose the Right Water Treatment machine

Picking an industrial water treatment machine isn’t one-size-fits-all! Follow these tips:

First, test your raw water quality—hardness, impurities, and flow rate dictate the right system. Second, prioritize energy efficiency—look for systems with variable frequency drives (VFDs) to save on power. Third, don’t skip after-sales support—we offer 24/7 tech help and 1-year free maintenance for our ro water treatment machine models.

FAQs About Industrial Purification Systems

-

Q: How long does a reverse osmosis water treatment machine last?

-

A: Membranes last 2-3 years, and the main unit 15+ years with proper maintenance.

-

Q: Can it handle high-salt industrial wastewater?

-

A: Yes! Our advanced RO systems handle TDS up to 50,000 ppm—perfect for manufacturing plants.

-

Q: How much space does the system need?

-

A: Compact design—5T/h models need ~10㎡, 50T/h ~30㎡. We’ll customize layout for tight spaces!

-

Q: What’s the payback period for your industrial water treatment machine?

-

A: Typically 8-12 months—thanks to water and energy savings!