Juice Filling Machine

We offer a complete range of juice filling solutions for both PET and glass bottles, supporting advanced processes such as hot filling and ultra-clean filling, ensuring the freshness, nutritional value, and long shelf life of the juice.

Home » Juice Filling Machine

Juice Filling Machine

Our fruit juice filling machine is one of the company’s key products. It uses gravity hot filling technology, maintaining a filling temperature of approximately 85–90°C or medium temperature of 68–72°C through a temperature-controlled reflux system.

Core Technologies & Application Types

| Filling Type | Suitable Products | Key Technical Features |

|---|---|---|

| Glass Bottle Filling | Premium juices, functional beverages | Precision filling, oxygen-free protection, visual positioning labeling, damage-free bottle conveyance |

| Hot Filling | Juices, tea drinks, beverages with pulp | High-temperature filling (≥85°C), bottle mouth sterilization, cooling tunnel technology, low dissolved oxygen control |

| PET Bottle Filling | Juices, sports drinks, vitamin-enhanced water | Aseptic environment filling, bottle shape adaptive clamping, CIP/SIP cleaning and sterilization systems |

| Can Filling | Juices, energy drinks, fruit vinegar | High-speed seaming technology, nitrogen flushing, precise level control, adaptable for thin-walled cans |

Process Highlights & Technical Advantages

Intelligent Filling System

Flow meter filling valves: Accuracy up to ±0.5%, suitable for pulpy and high-viscosity juices

5-in-1 integrated machine (rinse-fill-cap-label-code): Reduces contamination risks, improves efficiency

Bottle sterile air shower system: Maintains aseptic environment before filling

Temperature Control & Preservation Technology

Closed-loop hot filling temperature control: Real-time adjustment to avoid thermal degradation

Cooling tunnel spray system: Gradient cooling to prevent bottle deformation

Nitrogen overlay technology: Nitrogen protection before and after filling to reduce oxidation risk

Cleaning & Sterilization Assurance

CIP/SIP automatic cleaning systems: No disassembly required; automatic acid, alkali, and hot water sterilization

Sterile water bottle mouth rinsing: Dual rinsing before and after filling to eliminate recontamination

Environment cleanliness control: Filling zone can achieve up to ISO 14644-1 Class 5 cleanroom standards

Production Line Configuration Examples

Glass Bottle Juice Filling Line

Bottle washing → Sterile air shower → Vacuum filling → Vacuum capping → Inverted bottle sterilization → Warm bottle cooling → Labeling & coding → Case packing

Features: Suitable for high-acidity juices; non-contact bottle mouth filling maintains glass clarity and aesthetic appeal.

Hot Fill PET Bottle Production Line

Preform sterilization → Blow molding → High-temperature filling → Bottle mouth spray sterilization → Capping → Bottle inversion → Spray cooling → Sleeve labeling & packing

Features: Suitable for tea drinks and juices; heat-resistant bottle design; seamless integration between blowing and filling.

Can Juice Filling Line

Empty can sterilization → Vacuum filling → Nitrogen flushing → High-speed seaming → Pasteurization → Coding → Palletizing

Features: Suitable for cans and aluminum cans; filling speeds up to 28,000 cans per hour.

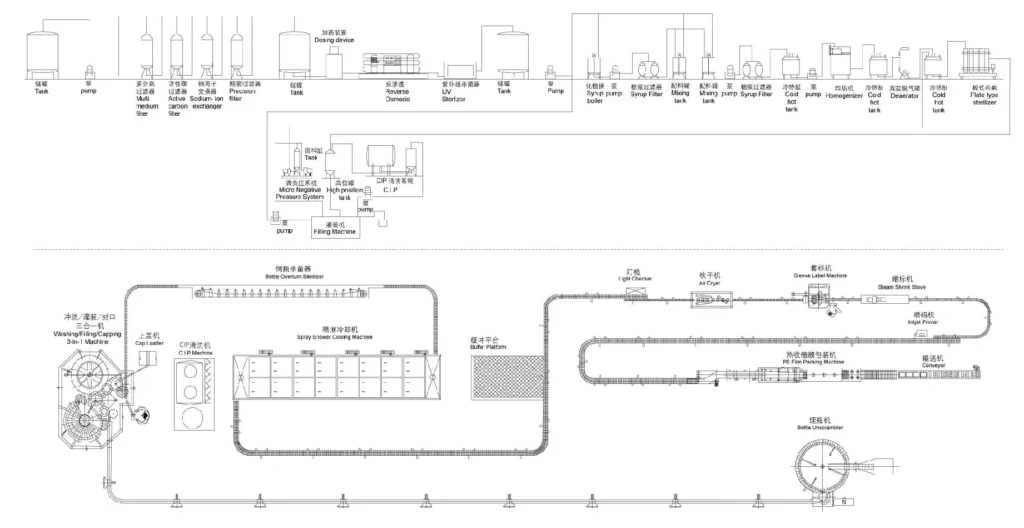

Total Solution Floor Plan

The complete fully automatic juice beverage production line mainly consists of water treatment equipment, fruit juice blending and sterilization systems, a 3-in-1 hot filling machine, pasteurizer, blow-drying equipment, labeling machine, packaging equipment, and a CIP cleaning system.

Product Features

High efficiency, stable performance, and user-friendly operation with durable construction and intelligent control for optimized production.

Advanced Intelligent Control

The machine is operated via a human-machine interface touch screen, with PLC program control and frequency converter for precise and efficient operation.

Custom Sterilization Solutions

For different juice types, we provide tailored sterilizers before filling, including UHT sterilizers, pipe-type sterilizers, and plate-type sterilizers to ensure product safety and quality.

Energy-Saving Heating System

The juice blending and sterilization systems require heat for operation, making the boiler an essential component to support production while reducing energy costs.

Gentle Bottle Conveying

The pressure-free conveying system ensures bottles on the conveyor belt do not squeeze or collide with each other, maintaining bottle integrity and smooth operation.

Juice Filling Line

Our hot-fill juice production line integrates water treatment, juice blending and sterilization, hot filling, labeling, packaging, and CIP cleaning. It ensures hygienic, efficient, and high-quality juice production, with smooth bottle handling and energy-saving operation, suitable for small to large-scale beverage production.

Water Treatment System

This system is designed for producing pure water and can also be applied in preparing raw water for juice, carbonated drinks, beer, and other beverages. The water source may come from municipal supply, underground wells, seawater, or rainwater.

Process flow:

Raw water tank → Raw water pump → Quartz sand filter → Activated carbon filter → Sodium ion exchanger → Precision filter → RO (Reverse Osmosis) → Finished water tank

Juice Drink Blending System

The system consists of a sugar-melting pot, blending tank, double filter, vacuum degassing unit, homogenizer, UHT sterilizer, storage tank, and CIP online cleaning system.

It is mainly used for juice preparation, sterilization, and the processing of fruit juice or mixed beverages before filling.

Production capacity ranges from 1 to 100 tons, available to meet different customer needs.

Juice Filling Machine

Juice beverages are typically filled using the hot micro-negative pressure filling method.

The PET bottles must be highly heat-resistant, able to withstand filling temperatures up to 85°C without deformation. It is recommended to use a high-temperature bottle blowing machine.

This juice filling equipment combines bottle rinsing, hot filling, and capping in one integrated system.

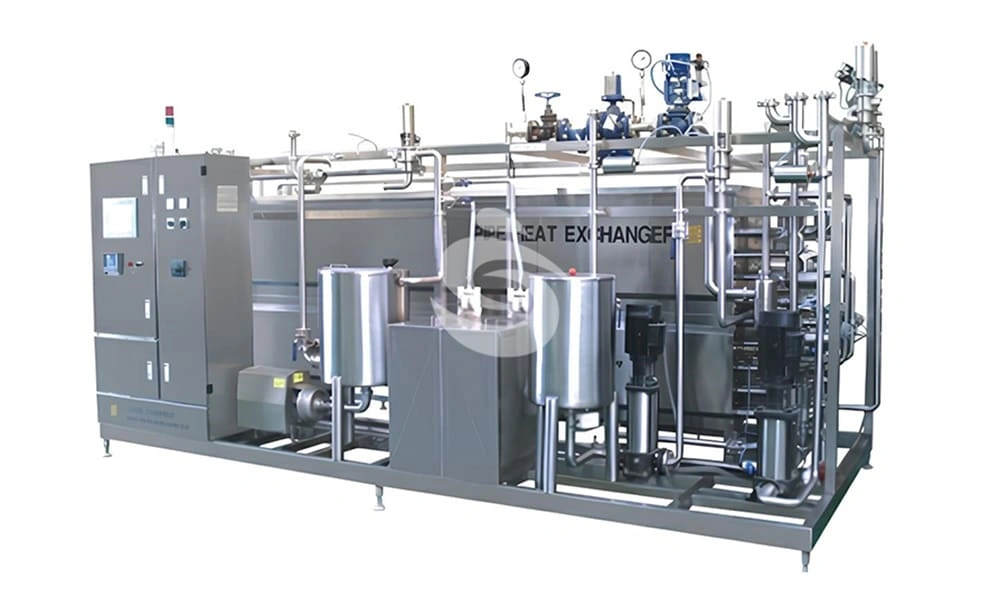

Pipe Type Sterilizer

This sterilizer is mainly used for beverages with granules, high viscosity, fiber content, or large pulp particles, as well as products with high acidity or those that are corrosive to dead angles.

It is capable of sterilizing at high and ultra-high temperatures ranging from 120°C to 140°C.

Plate Type Sterilizer

This equipment is suitable for heating, sterilization, heat preservation, and cooling processes required in fruit juice production.

It offers a capacity range of 0.5–50T/H, with sterilization temperatures between 85°C and 95°C, and a heat preservation period of 15–30 seconds.

Labling System

Our hot melt glue labeling machine is designed for high-speed, precise labeling of PET bottles, glass bottles, and cans. It uses advanced hot melt adhesive technology to ensure smooth label application, strong adhesion, and a neat appearance, even at high production speeds.

With features like stable operation, low glue consumption, and easy adjustment, this machine helps reduce production costs while improving labeling efficiency. It is widely used in beverage, food, and daily chemical industries, making it an ideal choice for large-scale automated production lines.

Packaging Machine

The bottle shrink wrapping machine is specially designed for packaging bottled products with heat shrink film, providing a neat, strong, and reliable outer package. It supports PET bottles, glass bottles, and cans, making it a versatile choice for different production needs.It can pack bottles into different groupings, such as 3×2, 4×3, or customized layouts, making transportation and storage safer and more convenient. The shrink film tightly wraps around the bottles after heating, ensuring a compact appearance and excellent durability.

Juice Filling Machine Product Introduction

High-speed hot filling for fruit juices, combining washing, filling, and capping in one system. Ensures hygiene and maintains juice quality.

| Model | RCGF8-8-4 | RCGF14-12-5 | RCGF16-16-5 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF40-40-10 | RCGF50-50-15 | RCGF60-60-20 |

| Rinsing heads | 8 | 14 | 16 | 18 | 24 | 32 | 40 | 50 | 60 |

| Filling heads | 8 | 12 | 16 | 18 | 24 | 32 | 40 | 50 | 60 |

| Capping heads | 6 | 6 | 8 | 10 | 12 | 15 | 15 | 18 | 18 |

| Capacity (BPH) | 2500 | 3500 | 6000 | 7000 | 10000 | 15000 | 17000 | 20000 | 24000 |

| Motor power(KW) | 3 | 3.1 | 3.1 | 3.1 | 3.8 | 5.6 | 7.2 | 9 | 12 |

| Dimensions | 2000*1500*2000 | 2400*1680*2400 | 2400*1780*2400 | 2400*1850*2400 | 3100*2200*2400 | 3600*2500*2400 | 4000*2800*2400 | 4500*3300*2400 | 5000*3600*2400 |

| Weight(KG) | 2000 | 2500 | 2800 | 3500 | 4000 | 5000 | 7000 | 8500 | 11000 |

FAQ

What is the difference between hot filling and aseptic filling?

Hot filling relies on high temperature during filling (typically ≥85°C) to achieve product sterilization and is suitable for acidic beverages. Aseptic filling is performed in a sterile environment at ambient temperature, ideal for neutral drinks and heat-sensitive juices, better preserving nutritional content.

How is uniformity and valve clogging prevented for pulpy juice filling?

We use large-flow piston valves or peristaltic pump filling systems, combined with low-speed mixing tanks and pipeline damping design to ensure even pulp distribution. Valves feature self-cleaning backflush functions to prevent clogging.

Does the complete line require a separate water treatment system?

It depends on the product process. We can provide integrated solutions including water treatment (RO reverse osmosis/ozone sterilization), syrup preparation, UHT sterilization, filling, and packaging. We also supply filling section equipment separately.

What certifications do you provide?

CE, ISO, SGS, and PVOC/COC/SONCAP documents if required.

Can the equipment handle different bottle shapes and capacities?

Yes. We use neck gripping technology and quick-change modules; no conveyor height adjustment is needed. Simply change star wheels, guide plates, and other components to adapt to various bottle shapes (200ml–1.5L).

Successful Cases

Proven success delivering high-quality water solutions.